Although most people would think that designing is the main part of my job/apprenticeship, another main thing within my job role is managing my time and efficiency. Whilst drawing up files, it requires us to work at a high pace to get jobs completed by a required date, some times the same day. We have to do this whilst making sure that the designs them self are perfect with no errors.

There are a number of ways in which we as a team within the design department make sure there are no errors with one another's work. To prevent errors in our work, then means that we all look better, but also we don't waste time correcting the errors at a later date, thus resulting in the fact that we are managing our time efficiently!

To prevent errors within our department:

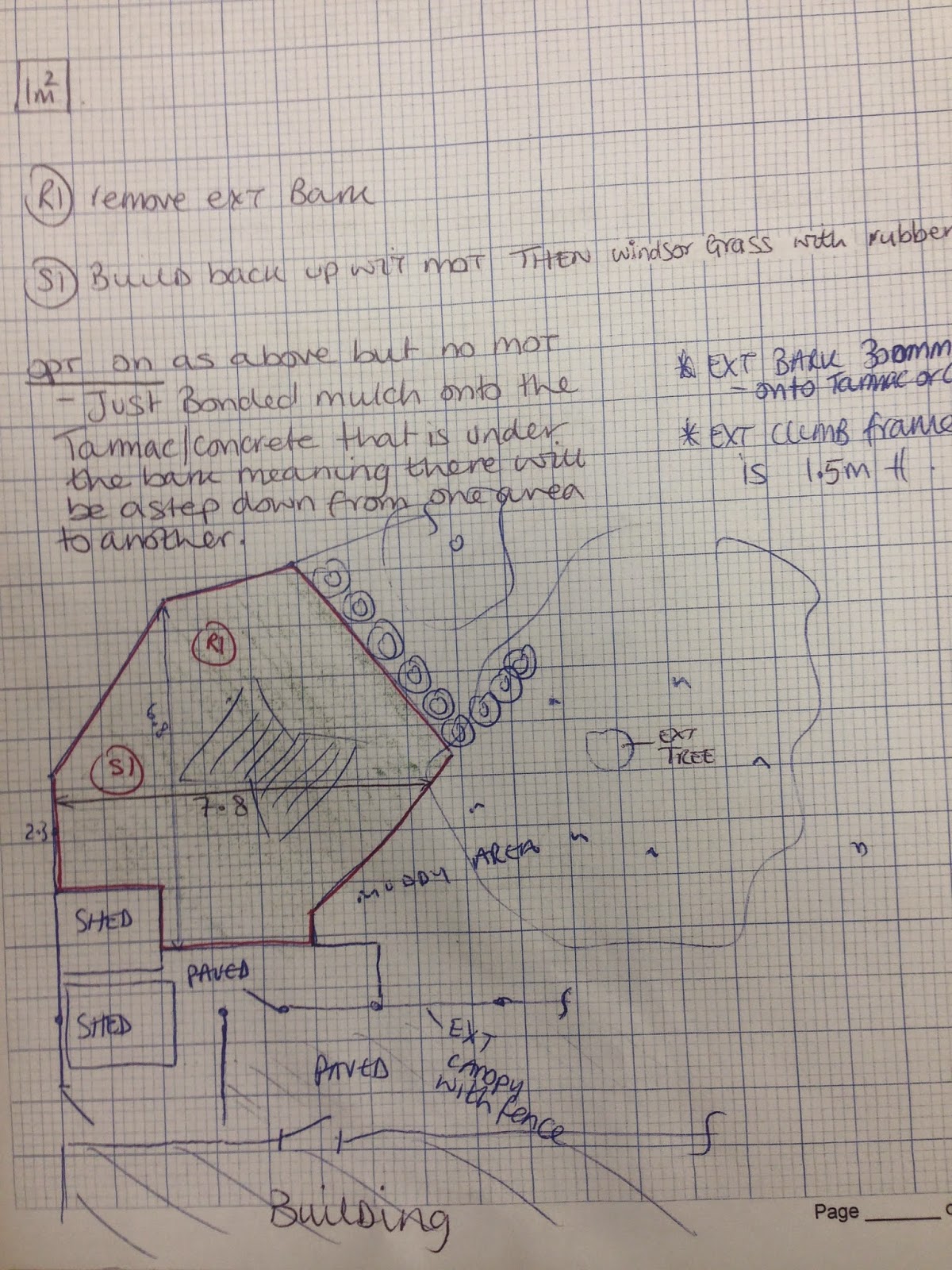

Whilst drawing a file, I make sure that I double check every thing; for example, the measurements of the existing area, the correct surfacing and equipment going in. Also as I'm only an apprentice designer, I like to ask questions to my trainer to ensure that every thing is correct.

When checking measurements, I draw the base of the area and visually show all the measurements on the drawing so I 100% know that there are no errors with the design. I will show this on a post blog when I present an example area of a 2D drawing that I have drawn up for a file.

Sometimes, when drawing a file, errors occur that the reps have made themselves. In this case, we have to email the reps for confirmation, and once they reply with the correct answer, thus means its perfect.

After completing a file, we do something called a peer assessment. This involves giving the design file to another full designer to check over. This means that they can find errors that you wouldn't see. After doing this, we then give the file to our manager Holly, who then does a final check of the file before sending it out to the client.

Peer checks happen between the full designers, due to my level as a designer apprentice, I am not able to check full designers work, simply because I don't have the knowledge yet. However, there are currently three apprentices within our design department and after drawing a file, we all check each others work; this then allows us to each learn how to check work, find mistakes and sometimes learn things that we didn't know before.

If I do happen to make errors within my work, these are some of the consequences that could happen:

I would waste time correcting the error when I could be in fact working on another file. This could then result in the job going out late, meaning an unsatisfied client.

If I made a mistake with the equipment or surfacing in regards to costing or amount, that action could loose money for the company. Further more meaning we could loose the job to other competitors.

If I made a mistake in regards to health and safety of equipment or surfacing, that would only effect myself and the company, but also the children using the play equipment. In an extreme case, death could occur. Here at Sovereign, we have something called 'Critical Fall Height', which allows us to work out the specific amount of depth that certain safety surfacing needs in relation to the height of the equipment. If I were to put the wrong depth serious injury/death could occur. This is the same situation with fall zones as each piece of equipment has its own fall zone area.

Here at Sovereign, a full designer draws an average of 6 total rating per day and 25 total rating per week. During the beginning of my apprenticeship, I would spend ages drawing up a file. The first week, I would take up to a day to draw just one file 2D only; and ensuring that it was 100% accurate. However this was understandable as I had just started. Over time, I have progressed to work a lot faster and have just recently set myself my first target to match a full designers rating.

You can see below, my bar work load for November, and I'm catching up with the full designers!

In regards to my apprenticeship, I also have to do college work and over a year and half, it is quite a bit! So to help track my progression, I have made my own matrix. By doing this I am able to easily track what work I have done, the location its stored so I can access it quickly and what outstanding work I need to complete.

.JPG)